EQUUS 175N The best forestry tractor made in Slovakia

Meet the most efficient forestry skidder in its category, EQUUS 175N! Its main attributes are robustness and high working efficiency together with its rate of return. The machine is easy to operate and complies with the most demanding criteria of today's customers. It is equipped with a state-of-the-art hydrostat and a perfect cooling system. This high-perform forestry machine is capable of driving on roads to distances exceeding 100 km in a speed of 40 km/h. The lowest centre of gravity in its class makes this machine a perfect choice for work in the most demanding terrain.

We are among the first manufacturers who use the state-of-the-art STAGE V class combustion engines. We have increased the transmission efficiency and improved the logic of the entire skidder, resulting in an overall savings of 20–30 % of fuel per 1 cubic meter of timber produced. This means savings in terms of fuel and lower emissions, as well as longer service life, and better price/performance ratio. Last but not least, it means a higher profit per one cubic meter and therefore the highest added value for the user!

Do you need a machine that can handle, cut and transport timber in bulk, in demanding terrain and in short periods of time? Select your version from our offer of EQUUS 175N skidders. Create own specification based on your needs and equip your dream machine with the accessories you need! ツ

Latest events and exhibitions:

Najnovšie akcie a výstavy

-

EQUUS at the exhibition in Libramont, Belgium - Demo Forest

EQUUS tractors were presented at the Demo Forest exhibition in Libramont (Belgium) by partner Clohse Group

-

EQUUS at the DLG Waldtage exhibition (Germany)

Presentation of EQUUS forest tractors at the DLG Waldtage exhibition (Germany - Lichtenau) from 9 to 11 September 2022.

-

Forest Exhibition in Norway also with EQUUS participation

From 16 to 17.9. in Oslo, Norway, a forest exhibition will be held with the presentation of EQUUS forest tractors.

NEW GENERATION EQUUS 2020 - changes and news

-

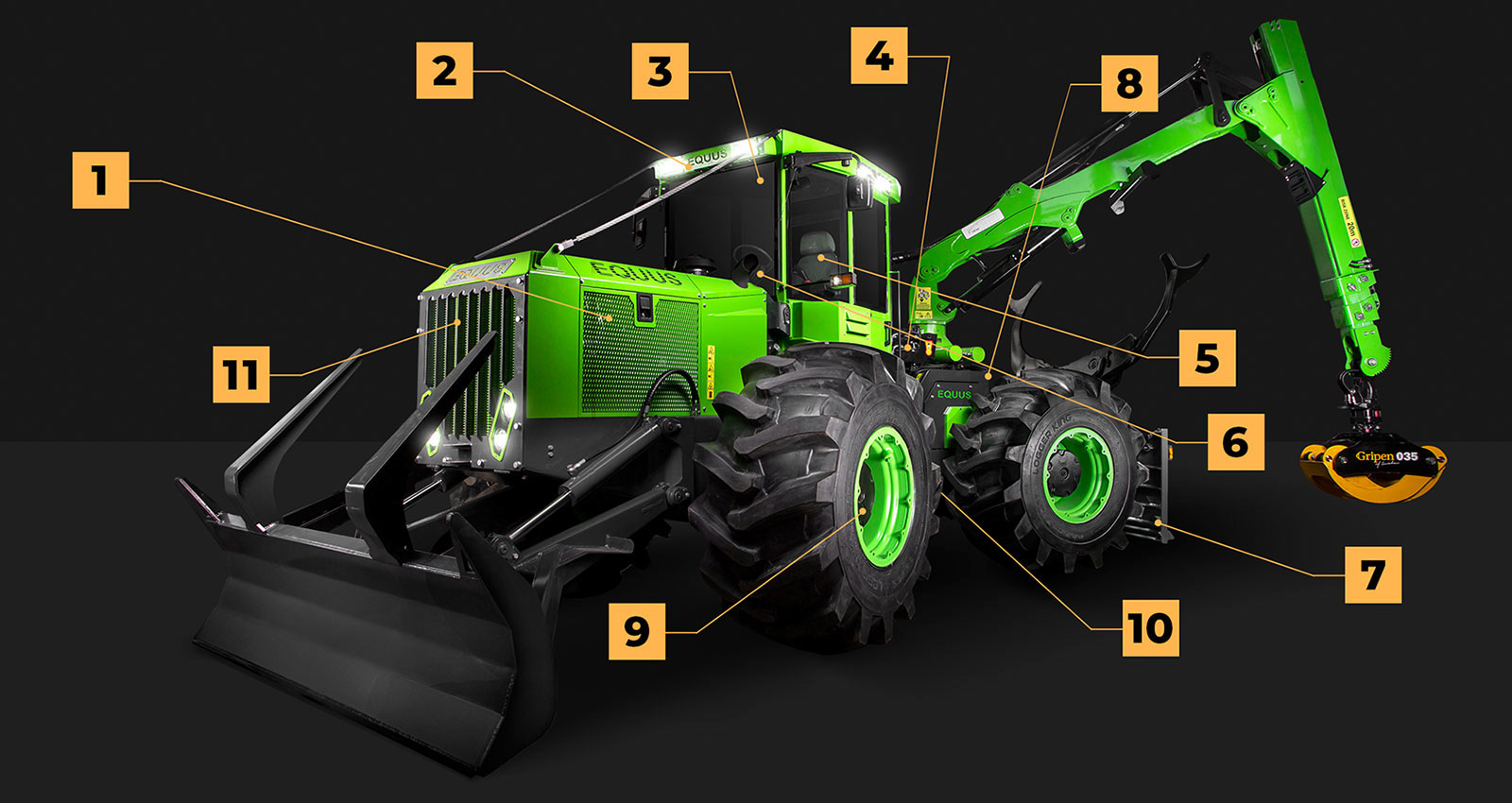

1. Motor

New engine CUMMINS with STAGE V - currently the highest ecological standard with manufacturer's certificate. 10% higher performance.

-

2. Cabin

Higher cabin with a better view of the crane, since new window was installed. Lower noise level (better insulation)

-

3. Air conditioning

New air conditioning system (from Webasto) New windows (smoked and safety glass) that reflect 20% more sun rays.

-

4. Hydraulics

New hydraulics - locking against slow falling of the hydraulic components, ETL control of the pumps

-

5. Work place

Electronically powered swivel seat / work place

-

6. New display

New display - for hydraulics. 8 x function for hydraulic components, 4 x function operator. New joysticks and keyboard for operating the hydraulics. New display for the engine.

-

7. Rear shield

Rear shield with a higher lift (1500 mm)

-

8. Winch

Winch with up to 15T per drum and up to 2x160 m steel rope with a diameter of 14 mm

-

9. Axles

NAF 17t axles, which are standard for higher classes - 6-cylinder engines.

-

10. Center of gravity

Low center of gravity of the machine

-

11. Radiator

Larger radiator with a cooling capacity of the engine at outside temperatures above 50 ° C.

EQUUS 175 N forestry tractor and its features:

-

Maintenance

Forestry tractor EQUUS 175N -

it is reliability, simplicity and affordable price. -

Design

Can you imagine a reliable, easy-to-use forestry tractor having no unnecessary electronic components that complies with the current demanding criteria?

-

Service Life

Robustness, economy and reliability are the attributes for the forestry wheeled tractor EQUUS 175 .

-

Engine – the first forestry skidder complying with the Stage V emission class.

As one of the first forestry skidders manufacturers, EQUUS has installed the most advanced CUMMINS B45 engine that meets the requirements of the most demanding STAGE V emission class.

With the power of 175 hp and the torque of 780 Nm, this direct-injection 4-cylinder engine delivers a performance comparable to larger and more expensive 6-cylinder engines, while being lighter, safer and more environmentally friendly.

-

Transmission – A unique hydrostat system

We have used a hydraulic-motor concept with enlarged volume of 300 ccm and 45° swinging plate. The higher volume of the hydraulic motor decreases its maximum speed, the swinging plate increases its effectiveness. The 1st gear is suitable for the speed of 0–18 km per hour and for dragging at optimum engine speed, which is the most important contribution to transmission efficiency. The 2nd gear allows the machine to travel easily over long distances without stopping at the speed of up to 40 km per hour.

-

EQUUS Cabin – the guarantee of the maximum safety

The cabin, which is an in-house production by EQUUS, offers the highest safety parameters! Not only does it meet the basic limits of the OPS, FOPS and ROPS standards, it even exceeds them. The cabin's position is as low as possible. It thus offers the most convenient way to get in and out of the cabin. Lighting is intelligently installed inside the body and therefore it allows, together with the use of high-quality safety glass, to eliminate the use of grille protectors. The cabin is equipped with door and optionally with a 270° rotating workstation.

-

EQUUS 120 hydraulic arm – robust and powerful solution

EQUUS produces own hydraulic arms that can be folded below the cabin level for more convenient road travel and/or for truck transportation. Its robust two-part structure with the net lifting power up to 120 kN and the technical design allows not only to easily handle but also to drag timber. Three different versions make it possible to choose the most suitable arm for any specific working conditions.

-

Performance anf power – the pride of EQUUS

By its weight and dimensions, EQUUS 175N fits into the middle-class segment, but its power and pulling force complies with the parameters of a higher class, i.e. 6-cylinder machines.

The 17 t / 4200 Nm axles, the higher-class timing case and cardans, wheelbase, low centre of gravity, the state-of-the-art engine combined with our own unique technical solutions enable us to achieve the performance and pulling force of higher-class machines, but for much lower price.

-

Frames and axles - great strength reserve

Frames of this forestry skidder are completely welded from the S690 high-strength sheets, which contribute to the high rigidity and long service life of the machine.

Axles manufactured by NAF with the parameters of 17 t / 4200 Nm are used as standard in higher-class machines. Intentional over-dimensioning of this key component provides our machine with a substantial reserve in durability and loadability even under the toughest operating conditions.